Candiani (Italy): Product Review

In this 30 second video we show you the future of large-scale, artisan textile production that combines robotics with ancient wooden shuttle looms and an ethical, vertical supply chain. The process is simple: you source your raw cotton from sustainable growers, you process it in an atmosphere with low fibre content to protect your employees, you dye and weave on site (on both modern and archaic looms), you then wash and shrink as the last process. However, with Candiani this is only the start as the company is constantly developing new systems that save waste (in energy and water) throughout the production line and in the processes performed on the garment after manufacture. For example, their factory-based denim lab has developed fast-fade dyes that mean less washing and a lazar technique that simulates years of wear without any water or human labour. But it doesn’t stop there. This far seeing organisation commissions cutting edge designers and tailors to make in their textiles, thus showcasing the versatility of denim.

–

www.candianidenim.it

Men’s File explores leather as a signifier of subcultural affiliations but also as a functional material that protects and serves the wearer, sometimes for decades. In this feature we present Lewis Leathers, The Real McCoy’s and the London Leather Man in an indulgent retro fantasy.

Riki’s brand is small, exclusive and doesn’t usually reflect what everyone else is doing. This genuine independence is apparent in everything the stylist wears and does.

This is the world of Fabian Jedlitschka and Pike Brothers. A realm in which post- war Americana and militaria are transposed, as they had been 75 years before, onto the picturesque German landscape and into the psyche of the nation’s fashionable youth.

There are certain street stylists, within the realm of male style, who ply their art on the same pavements on which George Brummel once trod. They are few, but their impact on the early moods that permeate menswear is immense.

Aboard this 1920s polished aluminium road rocket is Mr Derek Lee, a student of architecture and a young man of refined tastes. His suits are personally tailored in Hong Kong and his ability in finding original pre and directly post-war clothing is not in doubt.

Many years ago (Gary never says exactly when) Mr Eastman dismantled an ancient A2 flying jacket with the intention of finding out how it was made, with the idea of making a copy for himself. A few decades later and Eastman Leather Clothing is one of a select few of go-to brands for the serious connoisseur of replica militaria.

Painter, motorcyclist and collector of objects from the Old West, Nicholas Coleman lives on the edge of the old frontier town, although now very civilised, Provo, Utah.

A dedicated part-time Tiki-ist, hot-rodder and stalwart of the VHRA organisation, Jacqueline Davis is in fact a full-time professional graphic artist.

The innocence and elegance of pre-war Italy is encapsulated in this series of attractive vignettes featuring Alex Hills, Lucy Manley and an untouched 1935 Fiat 1500.

Just 5 years separate the four watches discussed on these pages, and each has their own unique personality and story to tell.

When Pomona resident Tim Scott told us ‘I wasn’t born into the hot-rodding world’ we imagined a newcomer who had recently stumbled on the scene and cynically recognised its visual potential.

Allow us to introduce you to a line of supercars (the 911 Targa to be precise), that started in 1967 and a far more contemporary ‘super-woman’, both with impeccable credentials.

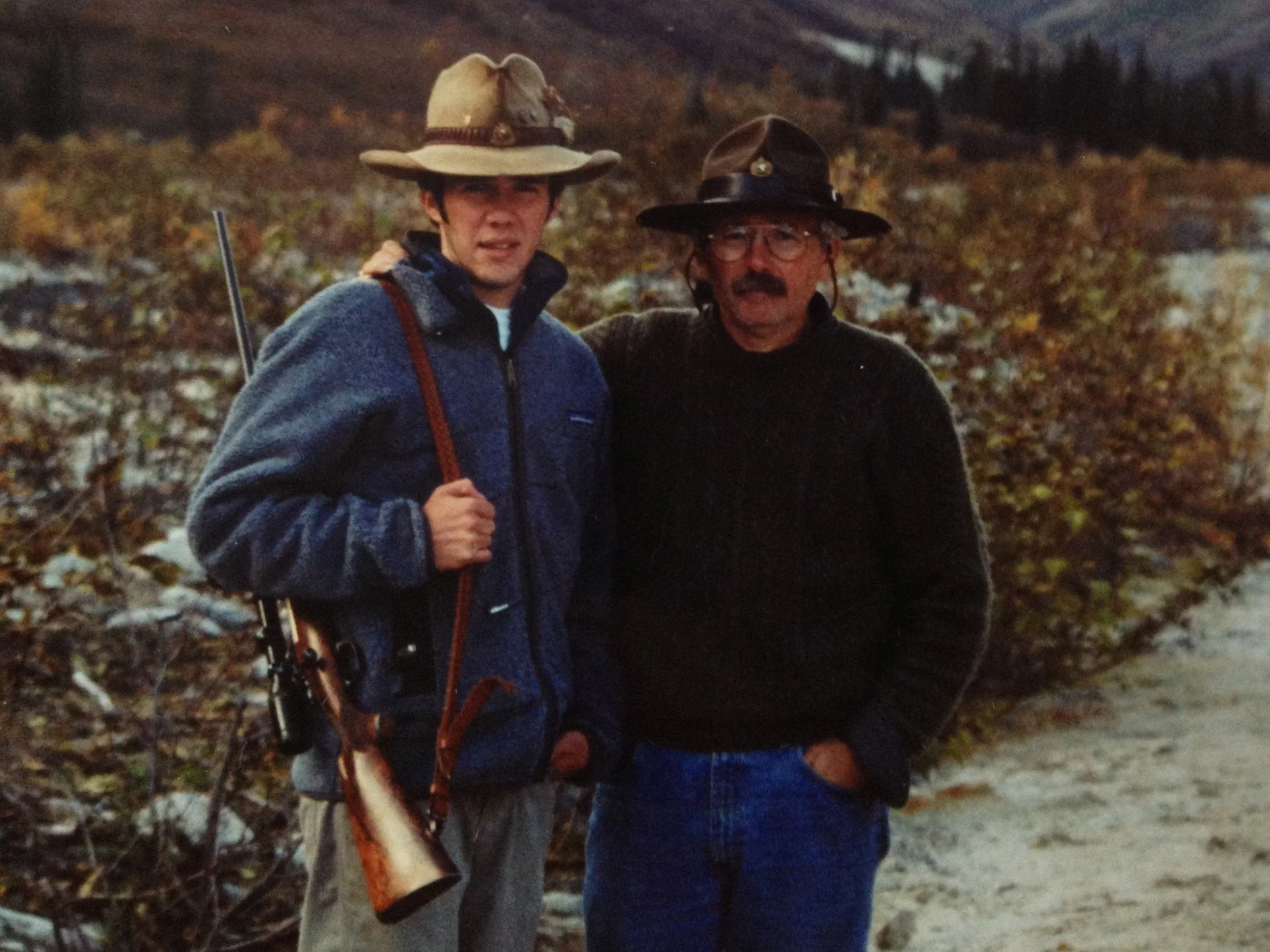

Named after a province in the south east of Norway, Telemarking is a form of skiing that owes more to practicality than to sport.

The Talented and ultra-stylish New York artist (more recently of Stockbridge, Mass.) gives a masterclass in sketching in charcoal from his studio on the Lower Eastside.

The Corvair was packed with innovations, but nevertheless controversial.

Flaviano Bencivenga is a gentleman of taste and action. A dedicated motorcycle collector and rider the Zurich-based shoe designer spends much time developing both new styles.

Pierre Girard (pictured) is a classic example of a one-man subculture. He creates clothing that he would like to wear and use on his extensive collection of motorcycles...

Northern Soul is a dance and music based subculture that flourished in the northwest of England at the end of the 1960s and into the 1970s.

Somewhere in East London, lost among the crowded grid of Victorian terraced housing and forgotten warehouses, an earnest craftsman hunches over his workbench.